Call: 08045817021

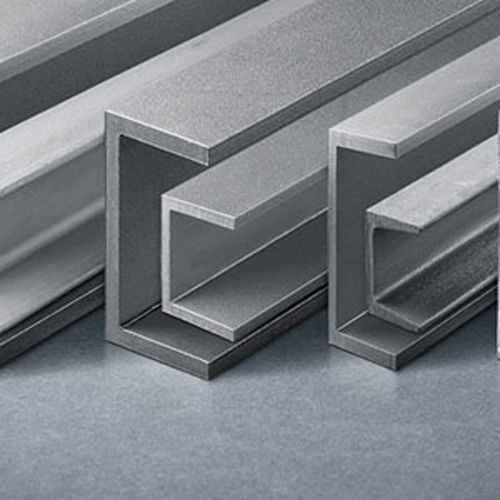

S S Channel

S S Channel Specification

- Steel Type

- Stainless Steel

- Grade

- First Class

- Shape

- C Channel

- Steel Standard

- AISI

- Surface

- Polished

- Application

- Construction

- Surface Treatment

- Polished Finish

- Weldability

- Excellent

- Material

- SS 304/316

- Rust Proof

- Yes

- Custom Lengths

- Upon order

- Channel Width

- Available on request

- Edge Type

- Square edge

- Channel Height

- Available on request

- Industrial Grade

- Yes

- Technique

- Cold Rolled

S S Channel Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About S S Channel

Specification:

- Specifications :ASTM A 276/A 276M,A 484/A 484M,A 564/A 564M,A 582/A582M,A 638 /A 638M,A705/A705M

- Dimensions :EN, DIN, JIS, ASTM, BS, ASME, AISI

- Channel :40mmx20mm to 300mmx300mm

- Thickness :3.0mm - 120mm

- Length :3MTR, 4MTR, 5MTR, 6MTR, or Custom Cut Sizes

- Type :C Channel, U Channel

Unmatched Durability and Rust Resistance

Built with SS 304/316 and finished with a polished surface, our channels guarantee outstanding rust-proof and corrosion-resistant properties, making them ideal for long-term applications in construction environments. Their robust industrial-grade quality ensures they withstand demanding conditions and retain their structural integrity over time.

Flexible Customization for Any Project

We offer S S Channels in a range of heights, widths, and custom lengths, all available upon request. This adaptability enables seamless integration into diverse construction designs, whether for frameworks, supports, or architectural features. Clients can benefit from tailored solutions that meet exacting project requirements.

FAQ's of S S Channel:

Q: How is the S S Channel manufactured for maximum strength and precision?

A: These channels are produced using the cold-rolled technique, which enhances dimensional accuracy and strengthens the stainless steel, ensuring high performance in structural applications.Q: What material grades are used for your S S Channel products?

A: Our S S Channels utilize SS 304 and SS 316 stainless steel grades, both meeting the AISI steel standard for first-class quality, ensuring excellent corrosion resistance and mechanical properties.Q: When can I request custom heights, widths, or lengths for the channels?

A: You can specify your requirements for channel height, width, or custom lengths at the time of order placement, allowing us to manufacture components precisely tailored to your project.Q: Where are your S S Channels supplied from?

A: We supply, export, and import S S Channels from our facilities in India, serving clients both domestically and internationally with reliable and prompt delivery.Q: What is the process for ensuring a polished and rust-proof surface on the channels?

A: Our finishing process involves advanced polishing techniques that create a smooth, reflective surface and further enhance rust-proof qualities. Rigorous quality checks ensure each channel meets industrial-grade standards.Q: How are these S S Channels typically used in construction projects?

A: Common uses include structural frameworks, support systems, and architectural detailing where strength, weldability, and aesthetic finish are critical. The C Channel shape lends versatility for varied structural applications.Q: What are the key benefits of using S S Channels with a polished finish and square edge?

A: The polished finish provides a sleek look and easy maintenance, while square edges offer precise fitting and excellent weldability. Combined, these features result in high durability, longevity, and superior project outcomes.

Price 300 INR/ Kilograms

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Channel Category

304 Stainless Steel Channel

Price 300 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Application : Construction

Grade : First Class

Surface : Polished

Steel Standard : AISI

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese