Stainless And Duplex Steel Rounbars

Stainless And Duplex Steel Rounbars Specification

- Standard

- Normal

- Tolerance

- H9, H10, H11

- Technique

- Hot Rolled & Cold Drawn

- Type

- Solid Round Bar

- Specific Use

- Industrial

- Processing

- Forged, Peeled, Bright

- Diameter

- 3.17 mm TO 350 mm

- Grade

- SS 310

- Finish

- Polished

- Application

- Construction, Industrial

- Length

- 6 meter

- Material

- Stainless Steel

- Magnetism

- Non-magnetic

- Corrosion Resistance

- High

- Single Piece Weight

- Custom

- Color

- Silver

- Heat Treatment

- Optional

- Surface Quality

- Smooth

- Shape

- Round

- Weldability

- Excellent

Stainless And Duplex Steel Rounbars Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Stainless And Duplex Steel Rounbars

The extraordinary combination of toughness, adaptability, and corrosion resistance in Stainless And Duplex Steel Rounbars accounts for their rising popularity. Due to their capacity to survive challenging climatic conditions and maintain structural integrity over time, these round bars have attracted considerable interest from a variety of industries. Due to their remarkable mechanical qualities, Stainless And Duplex Steel Rounbars are preferred for a variety of applications, including construction and manufacturing machinery and equipment. These materials can tolerate enormous loads and high temperatures thanks to their flexibility.

Specification:

Range :3.17 MM TO 350 MM DIA

- ASTM / ASME SA 276 :TP 304 , 304L , 309S , 309H, 310S , 316 , 316L , 316 TI , 317 , 347 , 410 , 420 , 430 ,431 , 440A ,B & C. , 446

- ASTM / ASME SA 479 :TP 304 , 304L , 304H, 309S , 309H, 310S , 310H , 316 , 316H , 316L , 316 TI , 317 , 321 , 321H , 347 , 347 H , 410, 430 , 431 & 444.

- ASTM / ASME SA 276 : UNS NO. S 31803 , S 32205 , S 32550 , S 32750 , S 32760.

Superior Corrosion Resistance and Surface Quality

Our round bars are crafted from high-grade stainless steel (SS 310), ensuring remarkable resistance to corrosion even in harsh industrial environments. The polished, smooth surface not only adds aesthetic appeal, but also improves longevity by minimizing wear and tear during use. This makes them highly suitable for demanding applications where durability and finish are essential.

Versatile Processing and Customization Options

We offer comprehensive processing including hot rolled, cold drawn, forged, peeled, and bright techniques, accommodating diverse project requirements. Customers can choose diameter sizes from 3.17 mm to 350 mm, and opt for customized single piece weights and optional heat treatment. Our bars conform to normal industry standards and precise tolerance levels (H9, H10, H11), ensuring reliable consistency in every order.

FAQ's of Stainless And Duplex Steel Rounbars:

Q: How do Stainless and Duplex Steel Round Bars benefit industrial and construction projects?

A: These round bars provide high strength, outstanding corrosion resistance, and superior weldability, making them ideal for use in tough industrial and construction environments. Their durability and consistent quality lead to extended service life and reduced maintenance costs.Q: What is the process behind manufacturing these round bars?

A: The bars are produced using advanced techniques such as hot rolling, cold drawing, forging, peeling, and bright finishing. Each process enhances the structural integrity, surface quality, and dimensional accuracy of the final product.Q: When is heat treatment recommended for these round bars?

A: Heat treatment can be optionally applied if enhanced mechanical properties, such as increased strength or hardness, are required for specific industrial applications. The necessity depends on the project's technical specifications.Q: Where are these round bars commonly used?

A: They are widely utilized in construction, infrastructure development, heavy machinery, and various industrial sectors across India, owing to their robust performance and adaptability in challenging conditions.Q: What are the usage instructions for weldability and finishing?

A: With excellent weldability and a polished finish, these round bars can be easily joined or fabricated using standard welding techniques. The smooth surface ensures a seamless weld and professional appearance.Q: Is custom sizing available for these round bars?

A: Yes, we offer a broad range of diameters, from 3.17 mm to 350 mm, and can supply custom single piece weights to match specific project requirements. Lengths are standardized at 6 meters for convenience.Q: What grades and standards do these round bars conform to?

A: Our round bars are produced in the SS 310 grade of stainless steel and comply with normal industry tolerances (H9, H10, H11), meeting the precise requirements of industrial and construction users.

Price 200 INR/ Kilograms

- Minimum Order Quantity

- 100 Kilograms

- Supply Ability

- 5000 Kilograms Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Round Bars Category

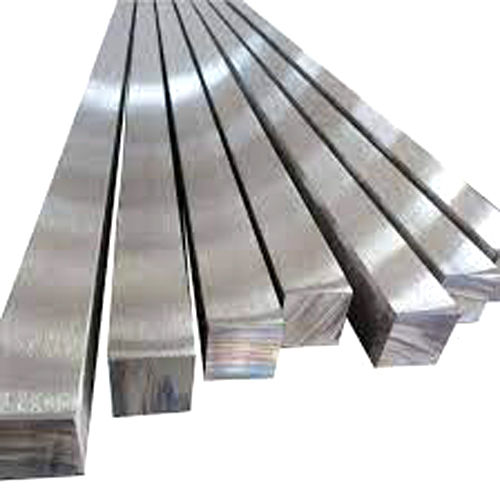

Stainless Steel Square Bars

Price 250 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Shape : Square

Corrosion Resistant : Yes

Finish : Polished

Material : Stainless Steel

Stainless Steel Hex Bars

Minimum Order Quantity : 100 Kilograms

Shape : Hex

Corrosion Resistant : Yes

Finish : Polished

Material : Stainless Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese